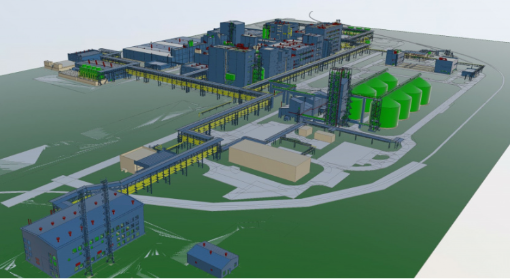

250kt deep grain processing & AmonoAcids production

Developing of the Digital Motivation Platform

Launch 25kt capacity Automotive & xSBU Paint Plant in Lipetsk with transferring of the technologies and products -400 types of raw materials, most of them were supplied to Russia for the first time

Ensuring the supply of materials and the launch of a new production line and product portfolios at the plant for the production of floor coverings in Kaluga of FORBO + a history of rapid improvements;

Kick-off of the 20MM Ceramic Bricks Factory and and driving up it to the rated capacity;

IATF16949, ISO9001+14001 implementation, documentation of Processes and Procedures, Licensing of dangerous objects class 3 and 2

Experience in FM global fire-fighting solutions and local FF legislation

SAP, Oracle R12, 1C ERP go-life projects and 1C+SAP+Cognos & R12+1C synergy projects.

Expertise in filtration solutions of high viscosity liquids against seeds and gel particles

Unique experience in high voltage electricity tariffication and supplying

— Бесплатные Сайты и CRM.

— Бесплатные Сайты и CRM.